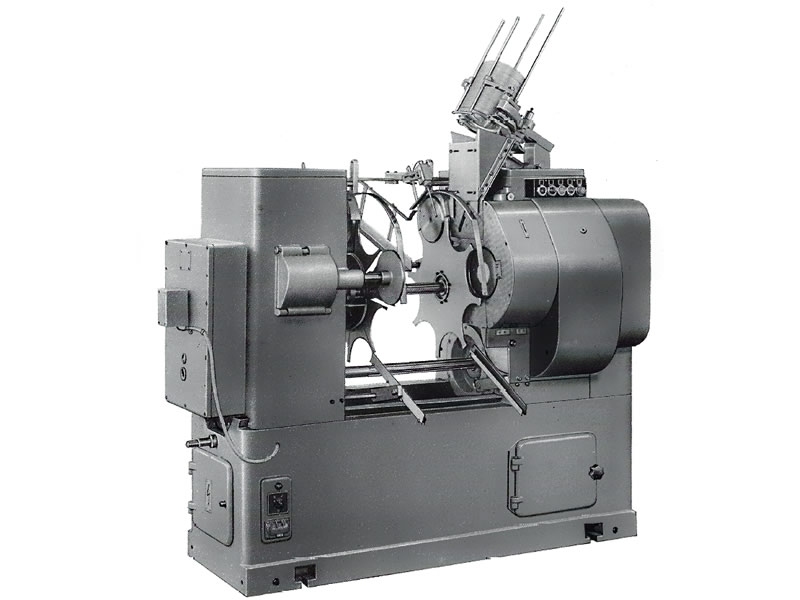

| Double die flanging and automatic bottom seamer

GENERAL CHARATERISTICS

This machine is used for the production of round cans. The can bodies, fed by a drop chute, are flanged with dies, then the bottom is seamed. The operator’s intervention is limited to load the curled bottoms into the special stock magazine equipped with a blade picker feeder, since the can bodies are automatically transported from one workstation to another by means of star conveyors. Instead of being flanged, the free end of the cans can be provided with an internal or external loop (or curl) for the application of pressure lids or be widened to obtain stackable cans. It is also possible to seam rings provided with an aluminum seal and pressure lid for cans of coffee, milk powder and other similar contents.

Other special versions are available on request. This machine is also designed to be coupled to the horizontal seamer model S.121 to form the transfer unit STAV 175 + S.121. Due to its great versatility, the machine has a wide field of application.

Now also in mod. STAV 175 – DN, equipped with an additional station for:

– necking with pads at one end for stackable cans

– necking with pads at both ends, equal and/or differential (aerosol cans). Can diameter: from 52mm to 175mm. Maximum weld overlap: 0.8mm.

FUNCTIONING

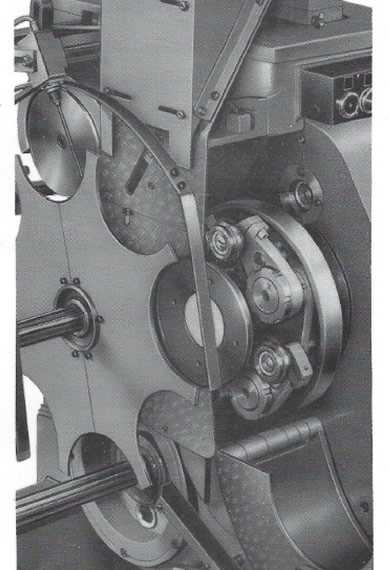

The can bodies, placed in the inlet drop chute, pass to the star conveyors which transport them to the various workstations. In the first, the flanging takes place which is carried out at the ends simultaneously by means of two dies.

This system allows an exact calibration of the bodies, which is particularly recommended for the subsequent seaming of the bottoms and lids. At the seaming station the flanged bodies are transported by the star conveyors together with the bottoms mechanically fed from the blade feeder or picker. The seaming takes place when the can is stationary by means of a four-roller seaming head (two for the first and two for the second operation), which guarantees an absolutely safe closure. The finished cans are ejected by a special lever and cam on an output chute.

The movement of the cans and the feeding of the bottoms are controlled by non-contact sensors, which control the stopping of the machine in case of need. This occurs when there are no bodies, bottoms or when the conveying stars are subjected to excessive stress due to jamming.

All the cams, the gears as well as the eight-position intermittent mechanism rotate in an oil bath. All fast-moving parts are mounted on ball bearings or needle roller bearings.

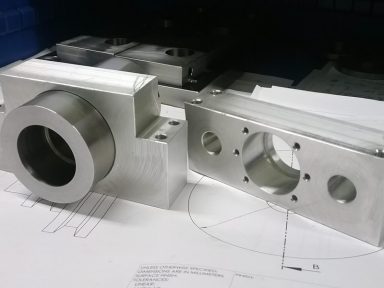

TOOLING CHANGE

The necessary replacements in the event of a change in diameter can be carried out in a maximum of one working hour. For the change of can height only, a few adjustments are necessary which take only a few minutes.

TECHNICAL DATA

Max Speed: 80 cans/min

Dimensional limits for boxes:

In classic execution: Ø from 66 to 180mm | H from 80 to 400mm

In special execution: Ø from 52 to 193mm | H from 66 to 400mm

Power: 3 Kw

Max sheet thickness: 0,4mm

Max dimensions: 183 x 99 x 185 cm

“It’s easier to love a brand when the love is reciprocated.”