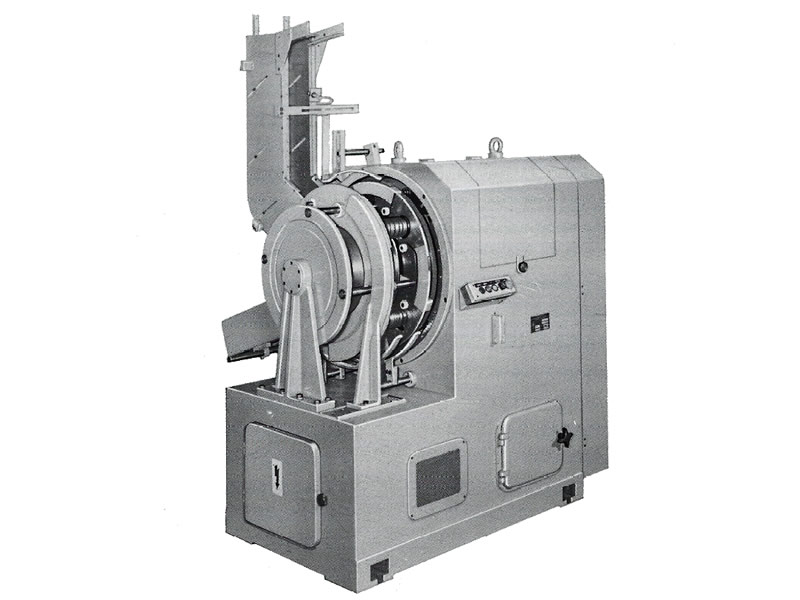

| Automatic beader machine

GENERAL CHARATERISTICS

The beading operation takes place by means of rollers with internal and external matrix: this allows the use of this machine even on finished can bodies, with the bottom already seamed. For special needs, the beading machine mod. RB-134 can also process finished cans with bottom and ring. The above is particularly advantageous when using automatic flanging machines or seaming machines: in fact, by beading the cans after the aforementioned operations, possible crushing during flanging and seaming operation is eliminated. The cans, which enter the beading machine mod. RB.134 through a gravity entry guide (which is equipped with presence control sensors), they reach the housings on the conveyor stars. After about half a turn, the beading operation is completed thanks to the intervention of the internal rotating shafts, driven by cams, and mounted on roller bearings. The beading machine mod. RB-134 is designed so that the peripheral speed of the internal rollers and the central drum are the same, in order to prevent slippage of the bodies to be ribbed and consequent abrasions of the lithography and of the internal painting. Subsequently, the bodies come out from the same side as the entrance, thus allowing the insertion of the Mod. RB-134 ribbing machine in production lines having a rectilinear arrangement.

The beading machine mod. RB-134 is designed so that the peripheral speed of the internal rollers and the central drum are the same, in order to prevent slippage of the can and consequent abrasions of the lithography and of the internal painting. Subsequently, the cans come out from the same side as the entrance, thus allowing the insertion of the Mod. RB-134 in production lines having a rectilinear arrangement.

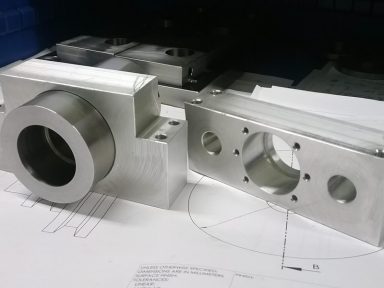

TOOLING CHANGE

The change of the beading rollers and the conveyor stars is done easily and takes about two hours. The height change only takes a few minutes. Power transmission takes place via roller chains, in addition the electrical system also includes an electronic torque limiter that stops the machine in case of excessive mechanical stress. This avoids damaging the moving parts.

TECHNICAL DATA

Max Speed: 150 cans/min

In simplified execution: 75 cans/min

Diameters: from 99 to 213 mm

In special execution: from 73 a 99 mm

Heights: from 80 to 300 mm

Max distance between beads:240 mm

Power: 2.2 Kw

Weight:1730 Kg

In simplified execution: 1630 Kg

Max dimensions: 155 x 100 x 170 cm

“It’s easier to love a brand when the love is reciprocated.”