| Automatic necker machine

GENERAL CHARACTERISTICS

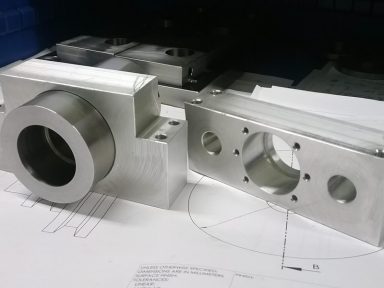

Machine for necking at one or both ends of round and irregular cans in a single operation with reduction of the same or differentiated diameter by means of dies, which according to technical needs have a fixed or expandable internal part, used to produce aerosol containers, cans for fruit juices and cans for soluble powder products and any other type of can falling within the dimensional limits indicated below that requires a necking operation. With the die necking operation, the can bodies are precisely calibrated to avoid any problems in the subsequent flanging operation. Due to the lack of high-speed rotating parts, the machine has a particularly quiet operation. This machine is fully automated.

The can bodies pass from the gravity feed chute to the conveyor stars, where they enter their respective housings and are transported to the necking station and subsequently, by means of special cam extractors, exit into the output chute. The movement of the stars is carried out by an intermittent mechanism which gives them a sinusoidal movement giving acceleration and deceleration to ensure the lowest wear on the mechanical parts of the machine. All machine movements are mechanical, implemented by hardened cams with rectified profiles. The necking dies slide on large cylindrical guides and all the moving parts are contained in sturdy cast iron uprights: the presence of large doors guarantees easy access to the internal parts. The cams and the intermittent mechanism are in an oil bath and the cam rollers are highly resistant. The machine is also equipped with a torque limiter that causes it to stop immediately if the conveyor stars encounter obstacles in their movement.

TRANSMISSION AND PRODUCTION CAPACITY

The transmission of movement occurs by means of chains. The mechanical speed of the machine is up to 120 cans/minute and the actual speed varies according to the size of the box to be necked, the length of the necking, the reduction in diameter and the thickness and hardness of the sheet.

TOOLING CHANGE

The format change time for the passage from one diameter to another is limited, as it only takes 30 minutes to replace the necking equipment and the conveyor stars. The transition to another can height requires an even shorter time, as only a few quick operations are required and takes place with the help of a millimeter precision ruler, calibrated on the cutting height of the can body.

TECHNICAL DATA

Max speed: 120 cans/min

Diameters: from 45 to 215 mm

Heights: from 80 to 350 mm

Max necking length: 5,5mm

Max sheet thickness: 0,32mm

Max weld overlap: 0,80mm

Power: 1,1Kw

Weight: 1025Kg

Max dimensions: 165 x 70 x 154 cm

“It’s easier to love a brand when the love is reciprocated.”